The electronics industry is constantly evolving, which means semiconductor manufacturers are constantly exploring new and innovative ways to enhance semiconductor manufacturing efficiency and quality to ensure their products function as designed.

There are several key strategies semiconductor manufacturers embrace to ensure their products meet customer needs. Here are a few ways that objective is accomplished.

Processes are Optimized for Quality Results

In all cases, maintaining and calibrating the equipment used in the manufacturing process must be scheduled and completed to ensure production doesn’t suffer. Modutek Corporation takes steps to ensure all equipment is cleaned, inspected, and calibrated on a regular schedule to reduce waste and enhance quality levels.

Yield management strategies are employed to maximize a producer’s output. The process includes monitoring and carefully analyzing yield information to identify and deal with potential issues quickly. That means clients’ semiconductors function as required, and end users are satisfied with their performance.

Automation Leads to Greater Efficiency

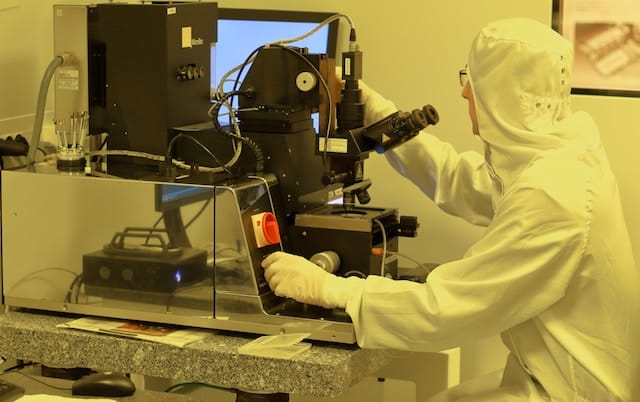

Manufacturers of all types quickly discover that automation and robotics speed up production while reducing errors and downtime. Semiconductors must meet rigid quality standards, which increases the need for exacting standards during the manufacturing process.

Using automated systems ensures materials reach the production line quickly, the need for manual labor is reduced, and overall efficiencies are improved. That means production costs are kept to a minimum, which benefits customers and the manufacturer.

Robotics eliminates repetitive tasks that lead to quality issues. That’s especially important during the manufacturing of semiconductors, as there is no room for error in their construction.

No one wants to see defective components used in products, and that’s always true with electronic devices. That’s why top semiconductor manufacturers go to unusual lengths to ensure their quality control process virtually eliminates defective products, and robotics play a significant role in achieving that objective.

Real-Time Decision-Making Enhances Outcomes

The majority of today’s manufacturers rely on accurate data when making crucial production decisions. Semiconductor makers monitor all production steps continuously to catch potential issues and deal with them quickly.

While human supervisors may detect some anomalies, computerized equipment collects and analyzes data faster than any human could. That means production quality rates are higher today than ever, and semiconductor manufacturers routinely collect various data throughout the manufacturing process to quickly identify bottlenecks or deviations from acceptable standards. Again, that type of agility reduces costs but, more importantly, also ensures the products function as intended.

Predictive Maintenance Boosts Overall Quality Rates

In the past, maintenance was scheduled when it was convenient. While that strategy had some advantages, downtime was common when components failed between the scheduled service dates.

Today, predictive analytics allows semiconductor manufacturers to accurately predict when maintenance is needed rather than waiting for a component to fail. That type of system reduces costly downtime, which helps the producer and customer as delays are less likely to occur. Taking care of maintenance proactively also enhances the safety of workers involved in the manufacturing process.

Conclusion

Semiconductor manufacturing is an exacting science that’s constantly evolving as technology advancements alter the design and use of semiconductors. To stay on top of the challenges involved in the manufacturing process, producers employ a holistic approach designed to reduce the odds of quality issues while keeping costs for clients as low as possible. In other words, modern semiconductor manufacturers take advantage of many techniques that are designed to enhance quality levels and cut production costs.

Leave a Reply