Reaction injection molding is a process for creating products that could cover the needs of certain industries. This process molds plastic-like materials into different shapes and objects at high temperatures.

The different applications of reaction injection molding will make it simpler to find solutions to problems for industries like medical, laboratory, and product development. If you need support bringing your designs to life, you can explore injection molding services by 3ERP for expert assistance. Learning about all the possibilities will open the door to new projects and products.

Interior Design

Products like doorknobs, handles, and doors are some of the most popular objects you can create with reaction injection molding. The simplicity of reaction injection molding makes it possible to design and create unique pieces that meet specific needs. The materials used for these items are resistant, easy to manipulate, and simple to paint, which makes blending with a room a lot easier.

Internal Components

With technology moving forward, many products become smaller, making it challenging to find fitting parts for certain projects. With reaction injection molding, it is possible to create custom-made parts that fit into any open space. Creating unique components while developing a prototype is the best way to make adjustments.

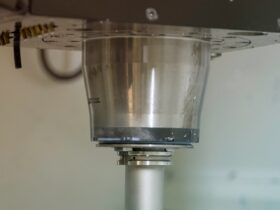

Laboratory Equipment

One of the most popular uses for RIM is for creating reliable, clean, and safe laboratory equipment. You can also use reaction injection molding to protect and enhance the characteristics of certain products, especially when they are mostly made of glass. The different products you can encapsulate with RIM will increase productivity in your laboratory.

Ensuring proper maintenance and cleanliness in your environment is crucial, especially when dealing with potential hazards. If you need professional help with sewage cleanup, visit here. Prompt action can prevent health risks and property damage, keeping your surroundings safe and hygienic.

Medical Devices

Medical procedures require specific equipment with unique characteristics and hypoallergenic materials. RIM is a safe and reliable way to create medical products. The medical industry keeps evolving, and it is important to keep up with new procedures and methods.

Gaming Devices

RIM works to help develop protection and unique components for gaming devices. This is one of the main applications of reaction injection molding that keeps growing and developing as entertainment options keep surging. Most industries need quick answers to evolving problems, and RIM is the perfect solution.

Leave a Reply