Optical homogenizers are optical components whose function is to transform the radiance from an input beam into a radiance distribution with increased uniformity. This transformation can be accomplished by various techniques, each with its own characteristics and optical performance.

Optical homogenizers play a crucial role in various industries, including medical, research, and manufacturing. To ensure the highest quality and performance of these devices, it’s essential to work with a reputable company like ECI that specializes in optical coatings and components.

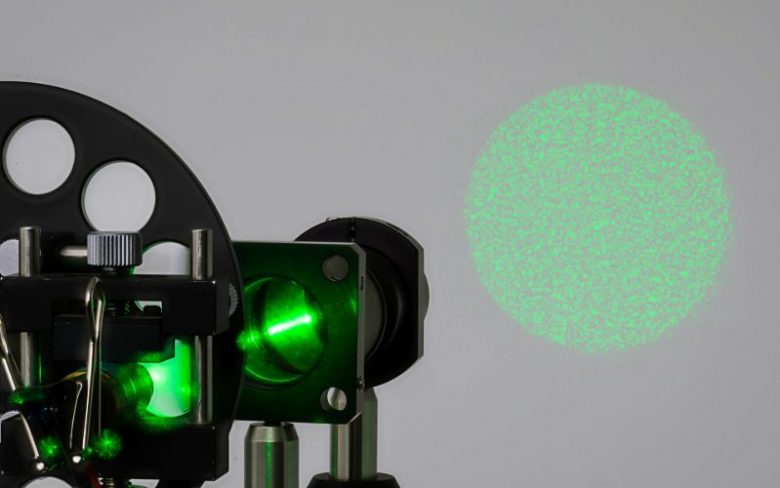

Diffractive Diffusers

The two main types of optical homogenizers are: diffractive diffusers and micro lens arrays. Diffractive diffusers are diffractive optical elements in which the wave nature of light is the dominant effect. They are usually used in conjunction with multi-mode lasers with a high M-squared parameter. In a typical use case, the diffractive optical homogenizer is placed along the optical path and then simply by free space propagation of the output beam, a new radiance pattern emerges.

A lens can be used as well to magnify or focus the desired output spot. The output radiance pattern can be characterized by a well bounded illuminated area of any desired shape depending on the intended application. Now, if the laser light is a highly coherent single mode laser, the output beam will exhibit some ripples in the otherwise uniform zone of illumination. These ripples are referred to as speckle noise which is common to coherent light illumination.

In some applications it may be detrimental but for others, such as thermal processing. If the input laser light is multi-mode, each mode at the output beam tends to add to the final radiance envelope, averaging out the speckle noise. A common application of a diffractive optical homogenizer is one in which the output from a fiber is used to illuminate a certain zone, typically in high-powered heat-based treatments. With the optical homogenizer element, the area of interest can be uniformly illuminated and with no light creeping outside of it.

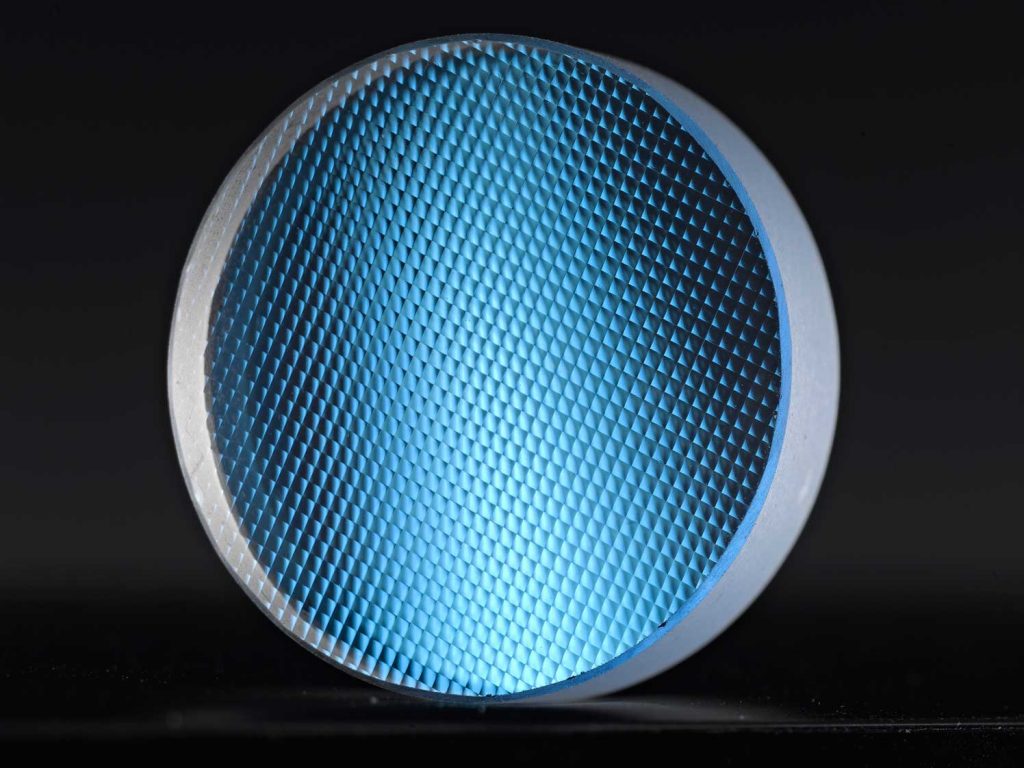

Micro Lens Array

The other type of optical homogenizer is the micro lens array. It consists of a series of lenses that create a multi spot array in a focal plane. When de-focused, the overlapping beams create a uniform envelope. In a micro lens array the focal length of each individual lens is constant. An important characteristic of optical homogenizers based on micro lens arrays is that given that they work by refraction, their wavelength dependence is much less than its diffractive counterpart. Hence, they can be used in those applications that demand good performance across a wide spectrum.

There is a subtype of micro lens array which is called the broadband optical homogenizer in which the focal length of each lens can vary. This is an important degree of freedom that generates improved uniformity and enables shaping the homogenized beam into various possible geometrical shapes, such as circles, that are impossible in ordered lens arrays.

It’s really interesting to read about Optical Homogenizes uses because we are also into the manufacturing of various ranges of Homogenizers. This is something unique. Thank you for posting.