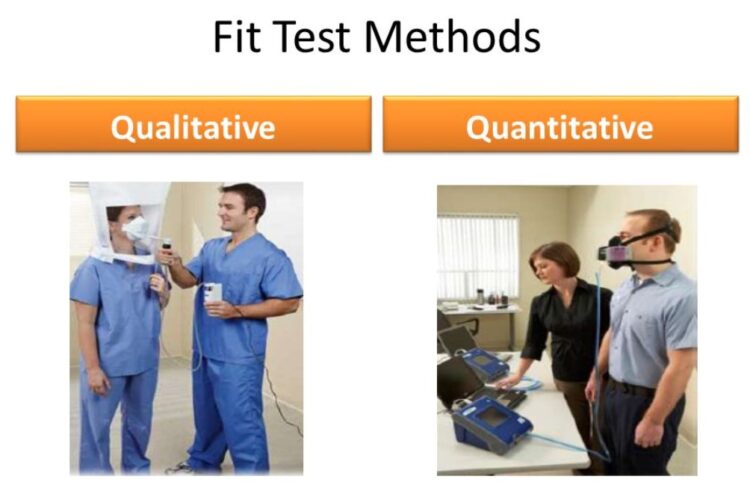

Quantitative Fit Tests

Quantitative face mask fit testing is established to measure the amount of leakage from a face-mask with the help of a machine tool. It measures the leakage of any gas, solution, toxic agent into the face-mask. To make it securely protected, the quantitative fit testing is done to provide complete protection and security into the face-mask. Well, quantitative fit testing equipment determines or aids in respiratory protection. There are three types of quantitative fit test techniques:

- Ambient Aerosol

- Generated Aerosol

- It gives complete control of negative pressure i.e. CNP

Qualitative Fit Tests

The qualitative fit test is a bit different from the quantitative fit test as it determines the use of the N95 face-mask as respiratory protection. In qualitative fit testing, the testing is done through taste and smell. With the taste and smell feature, the person can detect the leakage of the respiratory face mask. There are four techniques to detect this fit testing i.e. BITREX, ISOAMYLACEATAE, Irritant Smoke, and lastly the Saccharin.

However, when the fit test is completely over, each qualified worker has given a card posting the type, model, and sizes of the respirator. This is given when they got passed through a fit assessment. They also get an area-wide respirator fit synopsis report that incorporates a posting of every one of their representatives tested, the type, the model and size they are cleared to wear. Therefore, this is how the qualitative fit test works in reality.

Positive and Negative Fit Testing

Fit testing requires a direct positive or negative weight check that ought to be performed by the client on their respiratory defensive hardware. These are just appropriate for tight-fitting respirators and “ought to be utilized uniquely as a gross assurance of fit,” as indicated by the Australian Standard. This will work as a basic yet critical reinforcement seal assessment.

How Do Respirators Work?

A large number of laborers or workers are required to wear respirators in different work environments all through the United States. Respirators ensure laborers against lacking oxygen conditions, destructive tidies, hazes, smokes, fogs, gases, fumes, and solutions. These risks may cause malignant growth, lung ailment, maladies, or demise.

Respirators ensure the client in two essential manners. The first is by the expulsion of contaminants from the air. Respirators of this sort incorporate particulate respirators, which channel out airborne particles, and air-refining respirators with cartridges/canisters which channel out synthetic concoctions and gases. Different respirators shield by providing clean respirable air from another source. Respirators that fall into this class incorporate aircraft respirators, which utilize compacted air from a remote source, and independent breathing device (SCBA), which incorporate their air supply.

Conclusion

Well, all respirators that depend on a cover to-mask seal should be yearly checked with either qualitative or quantitative strategies to decide if the cover gives a worthy fit to a wearer. The qualitative fit test methods depend on an abstract sensation (taste, irritation, smell) of the respirator wearer to a specific test specialist while the quantitative method estimating instruments to determine face cover leakage.

Read more on safety in the workplace:

- 4 Lab Safety Tips Scientists Need To Know

- Bridging Safety and Efficiency: The Role of Cloud Software in Oil and Gas Operations

- Ensuring Electrical Safety in the Workplace: The Importance of Test and Tag

Leave a Reply