In manufacturing and construction, precision and efficiency are paramount. Every project demands meticulous attention to detail and the tools to ensure success. Clamps stand as unsung heroes among these tools, holding materials firmly in place to facilitate seamless operations. Not all clamps are created equal. Off-the-shelf options may only sometimes suffice for specific requirements. This is where a custom clamp emerges as the ultimate solution, offering tailored solutions to meet diverse needs with precision and effectiveness.

Understanding the Need for Custom Clamps

Custom clamps, unlike their standard counterparts, are tailored to meet the specific demands of unique challenges or specialized projects. Each project presents its own set of requirements, spanning from material dimensions to environmental factors.

Addressing these individual needs, these clamps offer unparalleled flexibility and adaptability. Whether tasked with holding irregularly shaped objects or securing materials in unconventional positions, custom solutions provide the versatility necessary for success.

Tailored Precision

One of the primary advantages lies in their ability to deliver precise results. Off-the-shelf options may need more specifications for a particular task, leading to compromises in quality and efficiency.

On the other hand they are meticulously crafted to fit exact dimensions and specifications of the project at hand. This precision enhances the overall quality of work and minimizes waste and errors, ultimately saving both time and resources.

Enhanced Performance

In industries where efficiency is key, the performance of tools makes a significant difference in outcomes. Custom clamps are designed to optimize performance by eliminating unnecessary features and focusing solely on what’s essential for the task.

This streamlined approach ensures maximum effectiveness without the added bulk or complexity often found in standard clamps. By aligning closely with the specific requirements of each project, custom solutions empower users to achieve superior results with greater ease and efficiency.

Adaptability to Diverse Needs

No two projects are exactly the same, and neither are their requirements. What works for one application may not necessarily work for another. These clamps offer the versatility to adapt to various scenarios, from delicate woodworking tasks to heavy-duty industrial applications.

Whether it’s accommodating different materials, angles, or mounting options, custom solutions can be tailored to meet the unique demands of any project, ensuring optimal performance across various environments and conditions.

Optimized Cost Efficiency

While the initial investment may seem higher than off-the-shelf alternatives, the long-term cost efficiency must be considered. Custom solutions are built to last, with durable materials and precise craftsmanship that withstand the test of time.

Additionally, their tailored design minimizes the risk of errors and rework, reducing overall project costs associated with material waste and downtime. By optimizing efficiency and minimizing waste, these clamps offer a compelling return on investment that far outweighs their upfront cost.

Tailoring Solutions for Specific Industries

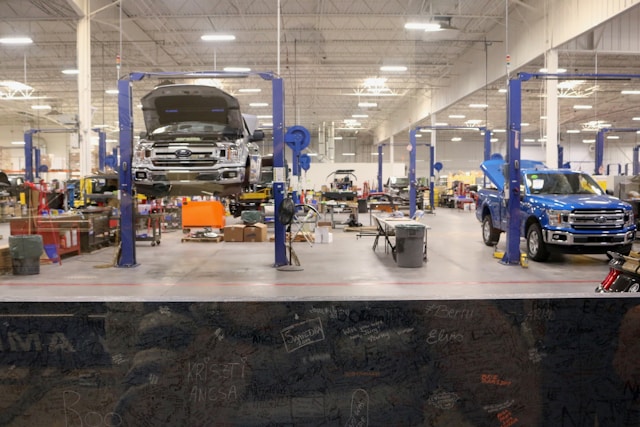

Different industries have unique requirements and challenges, requiring specialized solutions to address their needs. These clamps excel in this regard, offering tailored solutions for industries such as automotive, aerospace, woodworking, and construction.

Whether holding components in place during assembly, securing materials for precise cutting and shaping, or facilitating complex fabrication processes they are vital in driving productivity and innovation across various sectors.

Collaborative Design Process

The journey towards custom clamp solutions often begins with collaboration between manufacturers and end-users. This collaborative approach ensures that the final product meets exact specifications and expectations of the customer.

From initial concept development to final production, manufacturers work closely with clients to understand their unique requirements and challenges, providing expert guidance and insights. By leveraging the expertise and experience, manufacturers can deliver custom clamps that meet and exceed customer expectations, resulting in mutually beneficial partnerships built on trust and reliability.

Advanced Materials and Innovative Designs

Innovation is at the heart of custom clamp solutions, driving the development of advanced materials and innovative designs which pushes the boundaries of what’s possible. From lightweight yet durable alloys to cutting-edge 3D printing technologies, manufacturers are constantly exploring new avenues to enhance the performance and functionality of custom clamps.

These advancements improve the overall quality and reliability of custom solutions and enable users to tackle increasingly complex challenges with confidence and ease. By staying at the forefront of technological innovation, custom clamp manufacturers ensure their products remain at the pinnacle of performance, delivering unparalleled value to customers across diverse industries.

Conclusion

In a world where precision, performance, and efficiency are non-negotiable these clamps emerge as the ultimate solution for meeting diverse needs with unmatched accuracy and effectiveness.

By offering tailored solutions that align closely with the specific requirements of each project they empower users to achieve superior results while optimizing cost efficiency and minimizing waste. From collaborative design processes to industry-specific applications they are vital in driving innovation and productivity across various sectors, making them indispensable for success in the modern industrial landscape.

Leave a Reply