CNC machining is a type of production in which a software system directs the operation of equipment and machinery. It’s been a reliable production procedure for years, and it has evolved into one of the most used production systems.

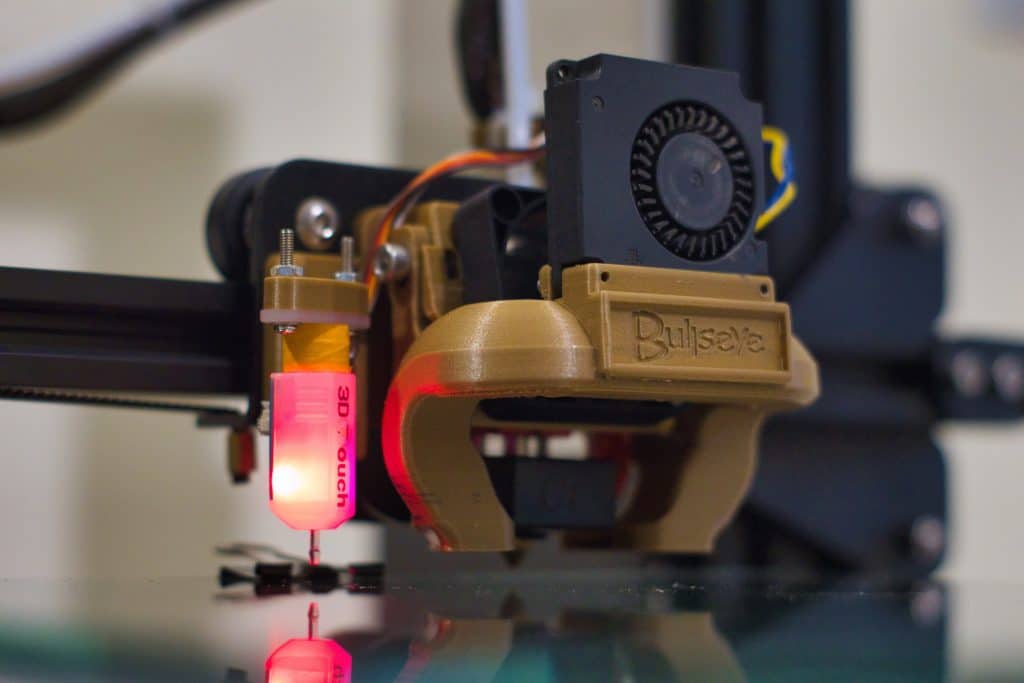

CNC machining has been threatened recently by quickly evolving technology: 3D printing and additive production of building the required object up layer by layer.

Following are a few things to think about to assist you in making your decision:

Precision

As you contrast the surface quality of a CNC machining part to 3D printers, you’ll see a significant difference. CNC-machined items can be moved from manufacturing to market as quickly as needed. 3D prints, on the other hand, frequently necessitate multiple phases to complete the production process. As a result, 3D printing is seen as a less efficient method than CNC milling.

3D printers lack the accuracy required for mission-critical applications. Also, when engineers employ Selective Laser Melting technology to manufacture 3D metal pieces, it can’t replace the precision of CNC machines.

Complexity

However, 3D printing can handle practically any complex geometry, which is one of its key advantages. By employing CNC, it minimizes the number of pieces that are typically required in an installation. As a result, 3D printing should be evaluated first for complicated parts that are difficult to fabricate.

There are currently software solutions that take advantage of this property to assist designers in choosing the most negligible mass and optimal rigidity via topological assessment before printing.

The tolerances that 3D printing systems can manage are different. CNC is also widely regarded as superior. This edge becomes less apparent when evaluating the lowest layer thickness attained by some 3D printing technology.

Complimentary Materials

If the proper tooling is utilized, a CNC machine can work with almost any material. Plastics like PVC, as well as metals including aluminum, stainless steel, and others.

However, the material adaptability of one 3D Printer is constrained. Its method can only print many materials, and ordinary printers typically only print photopolymers or thermoplastics.

Although modern 3D printers are more versatile and can print pieces made of metal materials, the technology is still in its early stages, rendering it more expensive and undependable.

Impact on the Environment

Material is frequently put into 3D printers, so there is less wastage, and any residual material can be reused. This is more environmentally friendly than CNC, which often entails cutting material and producing. 3D printing, on the other hand, has a maximum build size. As a result, 3D printing cannot contend with CNC in terms of maximum part size.

Bottom Line: Will 3D Supplant CNC?

In a nutshell, no. CNC is unlikely to be entirely supplanted by 3D printing. The key is to select the appropriate production procedure for your product, which could include 3D printing, CNC milling, or injection molding.

While 3D printing has several significant benefits, such as prototypes, decreased junk, and assemblies, CNC may compete on more significant works with particular materials, speed, and cost. While 3D printing has several significant benefits, such as prototypes, decreased junk, and assemblies, CNC may compete on more significant works with particular materials, speed, and cost – especially when you consider used machinery.

Leave a Reply