The 3D printing world is constantly evolving as new materials, techniques, and printers bloom daily. While this is an exciting prospect, you need to kick your creations up a notch by reconfiguring your current creation process, beginning with this list of ways to enhance 3D-printed end-use parts. By tapping into these ideas, you can unveil the potential of your 3D printer and significantly improve the performance and longevity of each creation.

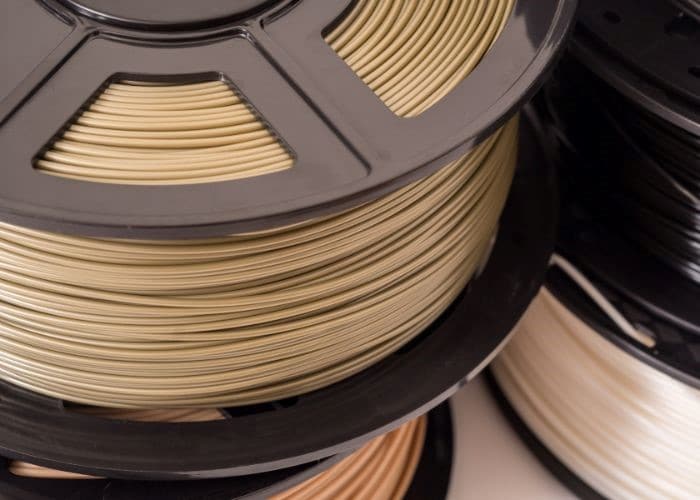

Material Options Matter

Material choice is a crucial factor in enhancing creation. While traditional filaments like PLA and ABS may not offer the necessary durability, advanced materials reinforced with nylon, polycarbonate, and carbon fiber supply increased durability and strength.

When designing 3D-printed end-use parts, considering the force of the material is crucial. Tough PLA emerges as a viable choice, offering superior strength and durability. Its high impact resistance and rigidity make it popular for creating robust parts that can withstand higher strain.

Fine-Tuning Print Settings

Perfecting print settings is the way to improve 3D-printed parts no matter what material you use. Tweaking factors such as layer height, infill percentage, and print speed can drastically change the strength and appearance of end-use parts. Finding the perfect balance may require some trial and error, but the resulting quality will make the effort worthwhile.

Post-Processing Techniques

Post-processing is essential for achieving the desired finish and strength of 3D-printed end-use parts. Techniques such as annealing can significantly improve a part’s strength and heat resistance while sanding, priming, and painting can give the part a polished and professional appearance.

Why Is Post-Processing Valuable in 3D Printing?

A post-processing technique like sanding, priming, painting, or metal plating is critical because it helps enhance the final product’s aesthetic appeal, giving it a more polished and professional look.

Furthermore, post-processing can lead to improved strength and durability. Techniques such as heat treatment can reduce residual stresses and increase the part’s toughness. But what about sealing? Sealing is a method that increases the part’s resistance to water and air, which is necessary for aerospace and other applications.

Advanced 3D Printing Methods

In addition to choosing superior filaments, exploring advanced 3D printing methods can yield impressive results for end-use parts. There are various advanced methods to consider when creating more accurate and complex parts, such as selective laser sintering or stereolithography.

These methods are much better than traditional fused filament fabrication (FFF) methods, ensuring the best functionality in the final product.

Design Considerations

Still, proper design is vital in enhancing 3D-printed end-use parts. Incorporating elements like fillets and chamfers can increase a part’s structural integrity while optimizing designs for material strength and weight reduction can result in strong and lightweight parts.

Ultimately, enhancing 3D-printed parts boils down to a combination of the right materials, fine-tuning settings, proper post-processing, advanced printing methods, and intentional design.

By considering these factors, it’s possible to create 3D-printed end-use parts that meet and exceed the expectations of even the most tech-savvy enthusiasts, pushing the boundaries of what’s possible with this incredible technology.

Leave a Reply