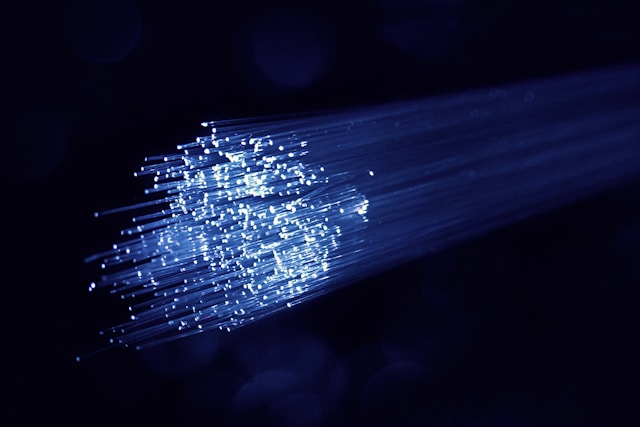

Overmolding has revolutionized cable assembly, offering superior durability, performance, and aesthetic appeal. This technique involves encapsulating a cable assembly with a protective layer of plastic or rubber, providing an additional shield against environmental factors. The ability to customize these assemblies further enhances their functionality, making them an essential component in various industries.

This article examines the steps involved in the overmolding process, the benefits of custom molded cable assemblies, and their applications across multiple sectors. The process is meticulous and designed to ensure maximum protection and durability for cable assemblies.

Steps in the Overmolding Process

The design phase often involves extensive collaboration between manufacturers and clients to meet all requirements.

After selecting the design, they inject the mold’s shape with the final product’s desired properties and inject molten plastic or rubber around them. This material fills the cavity, encapsulating the cables and connectors. This step requires precise control to ensure an even distribution of the material and avoid defects.

After molding, the assembly undergoes the cooling phase, during which the molded material solidifies and takes its final shape. Cooling must be carefully managed to prevent warping or other deformities that could affect the wire bunde’s performance.

The final step is the finishing phase, where any excess material is trimmed away, and the assembly is inspected for quality assurance. Features such as color elements and additives can be incorporated at this stage to enhance the cable’s functionality and appearance.

Benefits of Custom Overmolded Cable Assemblies

Custom molded cable assemblies offer numerous benefits, making them a preferred choice for many industries. One of the primary advantages is customization. The manufacturers can customize these to meet specific requirements, including selecting materials, color, and design features. This level of customization ensures that the assemblies are ideally suited to their intended applications.

Another significant benefit is durability. The overmolding process provides an extra layer of protection, shielding the cables from harsh environmental conditions, mechanical stress, and chemical exposure. It gives a longer lifespan and reduced maintenance costs, making them a cost-effective solution for demanding applications.

Another key advantage is flexibility. Overmolded wire bundles can be designed to accommodate various shapes and sizes, making them versatile enough for use in small spaces and complex installations. This flexibility is particularly beneficial in industries where space constraints are a concern.

Enhanced strain relief is also a notable benefit. The overmolded material provides additional support at critical points, reducing the risk of cable failure due to bending or pulling. This feature is crucial in applications where the cables are subject to frequent movement or mechanical stress.

Finally, custom overmolded wire bundles offer an aesthetic appeal. The ability to incorporate color elements and branding into the design makes these assemblies visually appealing, enhancing the overall look of the equipment they are used in.

Applications Across Industries

They are utilized in various industries, each with specific requirements and challenges. In the automotive industry, these assemblies are used in multiple components, including engine control systems, lighting, and infotainment systems. Their durability and flexibility make them ideal for harsh conditions within vehicles. These wire bundles ensure reliable networking and telecommunications equipment performance in the communications sector. Enhanced strain relief and environmental protection are precious in maintaining consistent signal quality.

These components also benefit home electronics. They are used in consumer electronics, including gaming consoles, home entertainment systems, and smart devices, providing robust connections and an attractive appearance.

These assemblies are crucial for diagnostic and therapeutic equipment in the medical field.

The military relies on overmolded wire bundles for mission-critical applications. These assemblies’ durability and environmental resistance ensure they perform reliably under extreme conditions, supporting communication, navigation, and control systems.

The oil and gas industry uses these assemblies in exploration and extraction equipment. The assemblies’ resistance to chemicals and harsh environmental conditions ensures continuous operation in demanding settings.

In the wind and solar energy sectors, these assemblies contribute to the efficiency and reliability of renewable energy systems. Their durability and flexibility are essential in maintaining their performance in various environmental conditions.

The industrial and OEM sectors benefit from the versatility and reliability of overmolded wire bundles. They are used in manufacturing equipment, automation systems, and machinery, ensuring seamless operation and minimizing downtime.

The over-molding process significantly enhances the performance and durability of cable assemblies, making them indispensable in various industries. Custom-molded wire bundles offer a reliable and cost-effective solution for complex applications by providing superior protection, customization, and aesthetic appeal. As technology advances, the demand for high-quality, durable, and customized wire bundles will only grow, underscoring the importance of this innovative manufacturing process. Partnering with reputable manufacturers ensures these assemblies meet the standards and deliver exceptional performance in even the most demanding environments.

Leave a Reply