Valves generally play a big role when it comes to piping. Valves help in controlling the flow of different substances in piping including fluids, gas, and steam. The act of controlling all these substances in piping is so essential. This means the substance can only flow through when the valves are opened.

There are different types of valves used in piping including ball valves, gate valves, butterfly valves, and many more. In this article, we are going to focus on trunnion ball valves and all you need to know about them. Learn more.

What Is a Trunnion Ball Valve?

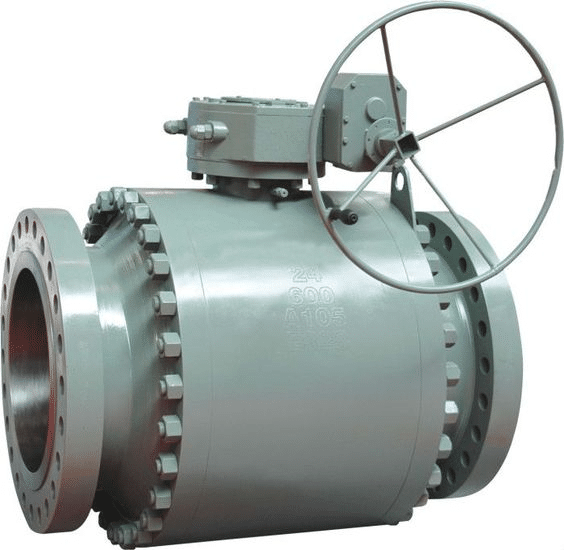

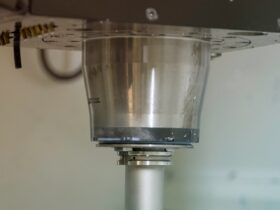

The trunnion ball valve is a vital device used mainly to control the flow of fluids, steam, gas, or even oil in the pipeline. This valve has a design of a quarter turn with a ball that rotates up to 90 degrees on its axis to either stop or to start the flow of fluid, steam, or even gas.

These ball valves have a disk designed in a spherical shape at the center, which rotates to control the start as well as the stop of the flow cycle. The disk often called the ball comes designed with a small elongated shaft at the top and bottom which are mechanically supported. For that matter, flow is directed depending on the position of a hole in the center of the ball.

For their adaptability, Trunnion-mounted ball valves are ideal in industries where such shut-off operation is highly needed. In case you are operating any industry make an effort to ship trunnion ball valves to help you in all processes involving the transportation of fluids and gas in piping.

How Trunnion Ball Valves Work

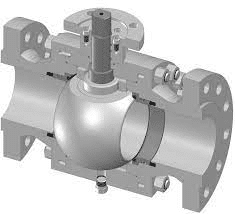

Most of the ball valves have a free-floating design, so the trunnion type is a design change. When it comes to the trunnion ball valve, the ball is attached to the stem on one end and is connected with a shaft called the trunnion on the other end. Due to this design change, the ball is held strongly in place.

For the floating ball valve, the ball is only connected to the stem and that is why it is called floating. Trunnion ball valves have a good number of benefits over free-floating valves, they are best for use in low, and high-pressure, and provide lower operational costs than free-floating ball valves.

The Structure Of Trunnion Ball Valves

The trunnion ball valves have a structure that looks almost like the traditional ball valves. What distinguishes them is that the ball valves have more mechanical anchors to provide support to the ball. The ball is offered solid support from the two ends on its x-axis. They hold the ball valve firmly in place and make it very convenient to control.

The trunnion-mounted ball valve has a cylindrical shape at its top and also at the bottom, which are also mechanically supported. With this, it is made ideal for larger diameters and higher pressure. In the Trunnion-mounted design, the ball is positioned by pressing the seat rings at the two ends.

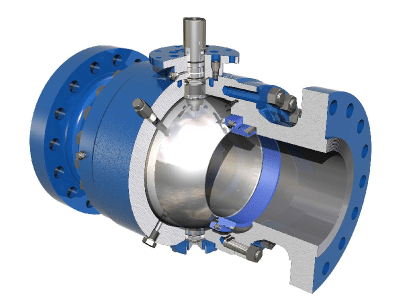

- Body. The body valve is the casing that holds it in place and provides support inside the ball valve. The material used for this design can be made up of different products depending on the type of work it is used for. Some of the materials that are commonly used include carbon steel, low-temperature carbon steel, stainless steel, duplex, Inconel, and super duplex.

- Ball. This is a disk with a sphere ball-shaped through which it rotates to block or start the flow. It is attached to the Trunnion at one end and on the other end attached to the stem. The ball is fixed in a position as it rotates. The valve’s seats are always in contact with this ball, which reduces the force.

- Seat. The seat of the valve is a feature designed to cover the ball. When you turn on the actuator, the seats keep the ball firmly in place, blocking off any access.

- Trunnion. There is a shaft in the trunnion ball valve that helps in holding the ball in position from below. This simple shaft is what we call the Trunnion. Its role is to keep the ball strongly attached. The Trunnion is also an extension of the spherical ball, while in other trunnion-mounted ball valves, it is connected to the spherical ball disk through welded joints.

- Stem. The stem of the trunnion ball valve helps in connecting together the ball and the actuator. The stem is connected to the ball with an additional shaft that helps in securing the ball in position. Also, it controls the movement of the ball.

Conclusion

Trunnion ball valves play a vital role in industries where shut-off operation is highly needed. Get these valves to help you in smooth operation in your industry. Also, it is important to have regular checks on them for any potential repair and maintenance work on the trunnion ball valves. Proper maintenance will be a big plus in your operation since it will reduce unplanned expenses involved when valves fail to operate.

Leave a Reply