Unique tools bring multiple advantages because they were designed to apply adhesives precisely and quickly, reducing the time required for manual application.

An adhesive spreader is a critical tool offering several benefits that significantly enhance the quality and productivity of caulking or sealing tasks. Their use is widespread across many industries, including construction, automotive, electronics and manufacturing.

An adhesive applicator such as Flip’n’Spread, offers a more accurate and even application to the entire surface, saving the material and reducing costs. The adhesive flow is precisely controlled, preventing over-application and spills, further optimising material usage. An adhesive spreader ensures the fluid is applied evenly and thoroughly, improving the quality and longevity of the bonds.

Adhesives, solvents and other liquids are often toxic and dangerous if not operated adequately. Such tools reduce direct contact with the fluid and improve safety, allowing the personnel to apply liquids without exposure to harmful chemicals. That reduces the risk of numerous health issues, including respiratory problems, chemical burns and allergic reactions.

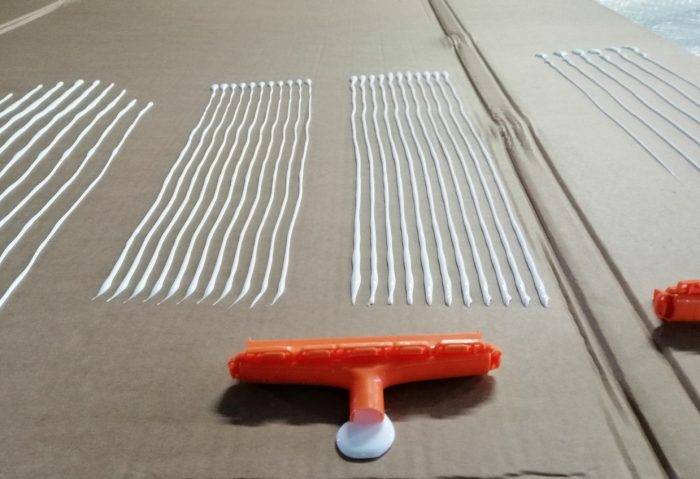

The adhesive spreader has a unique, user-friendly design

Adhesive applicator largely contributes to the efficiency of the process. Its ability to apply fluids consistently and evenly will minimise the risk of errors and reduce the need for repeats. The solution applied without a spreader can appear unprofessional and messy, with overflows and uneven lines. The unique design of Flip’n’Spread prevents all that and ensures liquid blends seamlessly with the adjacent materials. That is especially crucial in the areas where adhesives are visible, and the final result must be aesthetically satisfying.

The adhesive spreader can be used in a wide range of applications. Its incredible adaptability leads to remarkable outcomes and minimises the need for cleanup, as the excess adhesive is less likely to spill over onto surrounding surfaces. The Flip’n’Spread was designed to be user-friendly and is an ideal choice even for beginners.

The gadget ensures a cleaner, more aesthetically pleasing finish with smooth lines. It was made of durable material that could withstand repeated use in extreme conditions.

A creative solution Flip’n’Spread saves your time

An adhesive applicator is an innovative solution that improves productivity and saves time. Its distinctive design enables the users to apply sealants to numerous materials, including bricks, wood, insulation, panels, ceramics and stone. The applicator is available in the openings φ2.5, φ3, φ3.5, φ4 and φ5. They depend on the material viscosity, job and the users’ needs. To ensure the applicator fits perfectly, measure the aluminium tube on your PU pen gun.

An exceptional technical solution offers swift, steady and accurate application while utilising the material and offering more processed surfaces. Bricklayers used the classical mortar masonry method, lacking strength in earthquake areas. They started to use Flip’n’Spread, which spreads polyurethane foams evenly on larger areas to ensure strength and stability.

An adhesive spreader also works great on wood, enhancing the quality of the glued surface and speeding the completion of a project. The applicator attaches to liquids contained in plastic packaging and the foil sausage systems.

Can a high-quality manufacturer help you design an adhesive applicator?

Adhesive spreader is an essential tool in industries, meaning there is no room for error. When designing such a meaningful gadget, it is always best to seek guidance and help from the leading engineers. As a company, we specialise in technical solutions in the field of plastic packaging, and we also offer the production of plastic injection moulding tools.

To ensure our growth and to develop excellent products such as Flip’n’Spread, we are constantly educating and implementing innovations. We offer comprehensive solutions, including the design of an adhesive applicator, engineering, development, prototyping, 3D printing and help with the startup processes. Our client products will also receive extensive testing, troubleshooting, repair, maintenance and consulting services.

The final products will fit specific applications and comply with all the certificates. The high standards are confirmed by the standard ISO 9001: 20015. We can assure you that products are engineered for consistent performance and can have various colours, adjustable features and unique patterns.

The adhesive applicator offers unmatched versatility

The adhesive spreader was designed to ensure durability and adaptability. It is of HDPE, a reliable material with a perfect balance of lightness and strength. That is important as versatility is crucial in industries requiring different adhesives. Impeccable design improves product appearance and aesthetics while increasing productivity, reducing waste and contributing to significant cost savings.

Adhesive applicator Flip’n’Spread is the highest of quality, utilising state-of-the-art technology and the best materials. Because our clients value reliability and stability, we stand by them through the entire process – from design to final products. In the current situation, agile adaptability is paramount. The companies thriving are the ones that can adapt rapidly. We can make such change as seamless as possible because nothing in our business, is left to chance, and we ensure your dispensing solutions are tailored to your requirements. In the process, we utilise automated systems and advanced machinery, guaranteeing consistency and maintaining the highest quality standards.

Featured image courtesy of image courtesy of the vsisi.co.uk website.

Leave a Reply